Inside the Fully Automated Watch Movement Factory

Watch making automation - Life in Classic

The Quest to Automate a Mechanical Heart

How do you fully automate the making of a mechanical movement? The answer blends robotics, micromachining, software, and centuries of know-how. Today, modern factories chase repeatability and precision at the scale of human hair. However, they also respect the craft that gave watches their soul. The goal is simple: produce consistent parts and assemble them flawlessly, at speed and with traceable quality. Yet the path is anything but simple.

First, engineers deconstruct the movement into modules: barrel, gear train, escapement, and regulation. Then they map every step, from metal coil to ticking heart, into a digital plan. Moreover, they design fixtures, grippers, and sensors for each tiny task. In parallel, they build a data backbone that records every action. Consequently, machines learn, control charts update, and processes tighten. In the end, the factory behaves like a single instrument, tuned for accuracy.

From Raw Materials to Micro-Parts

Automation starts with parts. Plates and bridges emerge from CNC mills and stamping presses that run unattended with pallet systems. Meanwhile, gear teeth form through hobbing, wire EDM, or etching, then move to automated deburring and polishing cells. Additionally, parts pass through ultrasonic cleaning, drying tunnels, and precise coating steps. Every tray carries a barcode or chip, so software tracks location, batch, and results.

Balance springs and jewels demand special care. Therefore, alloy ribbons roll to exact thickness, get cut with lasers, and coil under controlled tension. Heat and chemistry set their elastic memory. In parallel, synthetic rubies are grown, drilled, and burnished by machines that measure size on the fly. Furthermore, robots gauge hole concentricity and surface finish, rejecting outliers in real time. As a result, tolerances hold to microns before any assembly begins. Because the raw parts are consistent, downstream stations can run faster and with fewer stops.

Robots That Assemble With Gentle Hands

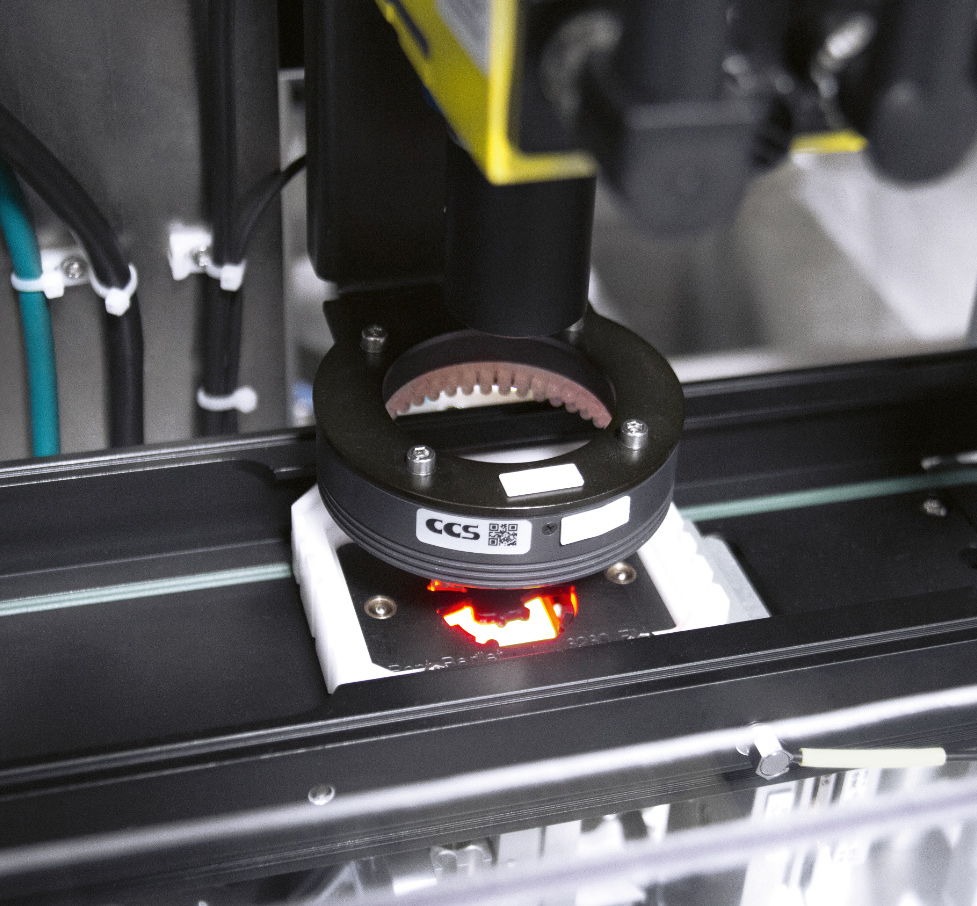

Assembly is the toughest frontier. Yet it is where automation now shines. Kitting systems feed parts in oriented trays, while micro-grippers pick components without scratching them. In addition, force sensors ensure screws seat correctly and wheels mesh cleanly. Vision systems align pivots with jeweled bearings and verify endshake. Then tiny pumps deposit oil in femtoliter doses, exactly where it belongs, and nowhere else.

Factories pre-build modules to simplify final work. For instance, barrels get springs, covers, and lubrication as a set. Likewise, escapements arrive as matched pairs of pallet and wheel. Consequently, the main assembly line focuses on stacking, fixing, and testing rather than hunting for parts. Cobots share space with technicians in clean rooms, handing off delicate steps where human judgment still adds value. However, each action still logs to the manufacturing system. Therefore, the line can pause, correct, and resume without chaos.

Testing, Regulation, and Digital Traceability

As soon as a movement ticks, a wall of tests begins. First, machines check amplitude and rate in multiple positions. Then climate chambers cycle temperatures to spot drift. Additionally, demagnetization tunnels clear any residual fields. High-speed cameras inspect dial side visuals, while lasers mark serial numbers for lifetime traceability. Most importantly, software ties every data point to a unique movement ID.

Automated regulation closes the loop. Controllers move the regulator index in tiny steps while measuring the result. If needed, systems adjust beat error and endshake. Moreover, balance assemblies undergo dynamic checks, with robots adding or relocating micro-weight screws on advanced designs. When targets hold across positions and temperatures, the movement moves on. Finally, sealed trays carry it to casing, prepped and verified. Because feedback flows to earlier stations, the line improves without waiting for audits.

People, Craft, and the Limits of Full Automation

Can everything be automated? Not quite. Finishes like black polishing, sharp interior angles, and mirror bevels still favor skilled hands. Likewise, ultra-thin hairspring pinning and exotic complications challenge robots with edge cases. Nevertheless, automation frees artisans to focus on the hardest and most visible work. In turn, customers get reliability and beauty in one package.

Ultimately, the fully automated movement is a partnership. Machines bring endurance, consistency, and relentless measurement. Humans bring insight, creativity, and final judgment. Together, they push accuracy higher and defects lower. As materials evolve and software learns faster, even more steps will shift to lights-out production. Yet the heart of mechanical watchmaking endures, now amplified by code, sensors, and quiet robots that work through the night.